Joe McCartney’s dream began in 1947, in an abandoned gas station where he built equipment for the manufacturing of wooden toys. The company moved to a larger facility in 1954, and evolved into making parts for the booming polyethylene business, primarily supplying parts for poly-gas oil compressors to the Ingersoll Rand Company.

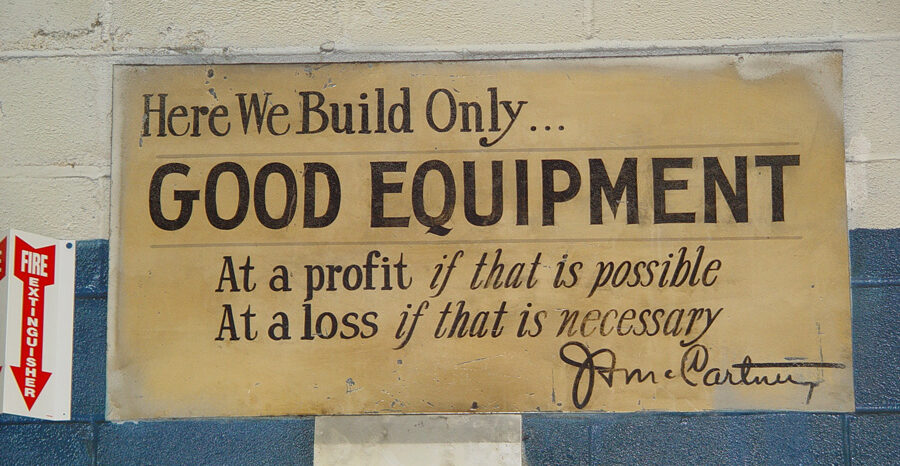

From the very beginning, McCartney Manufacturing has had the Joe McCartney philosophy, expertise and the products necessary to focus on close tolerances and fine surface finishes. This ability to do precision machining was a perfect match for high pressure production equipment used in low density polyurethane production and the equipment required to produce and contain high pressure water for waterjet cutting.

In 1951, McCartney started the manufacture of high-pressure valves and fittings as required by the low-density polyethylene industry. This was in the early stages of LDPE production in the United States. During the period 1951 through 1960, the manufacture of these components was performed based on customers’ detailed machine drawings.

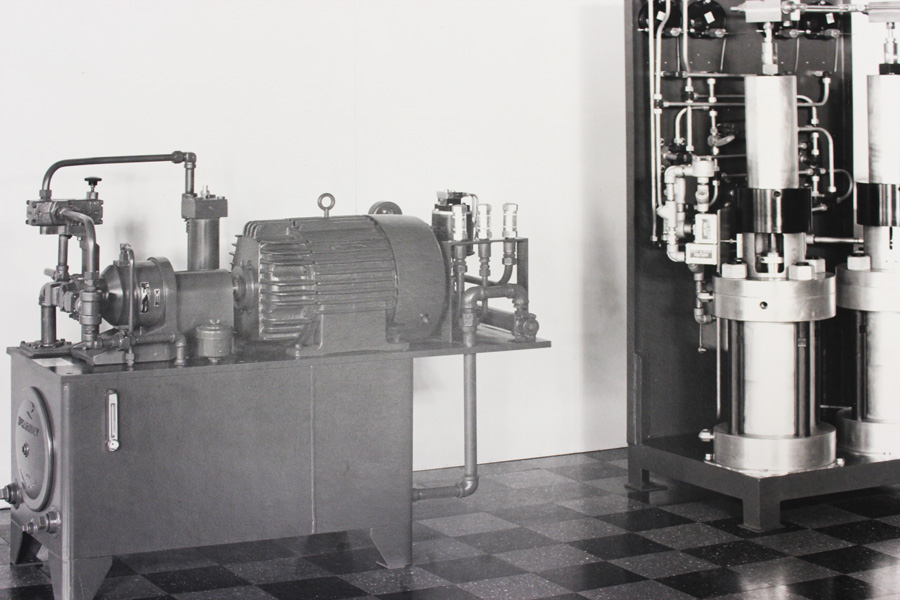

In 1960, McCartney started manufacturing catalyst injection pumps, modifier pumps, H.P. tube fabrication, H.P. double-pipe/tube heat exchangers, tubular reactors, let-down and safety dump valves, recycle ethylene gas filters and other specialty high-pressure equipment as required by the industry. Valves are furnished with various types of operators including manual, pneumatic, hydraulic, electric and electro-hydraulic.

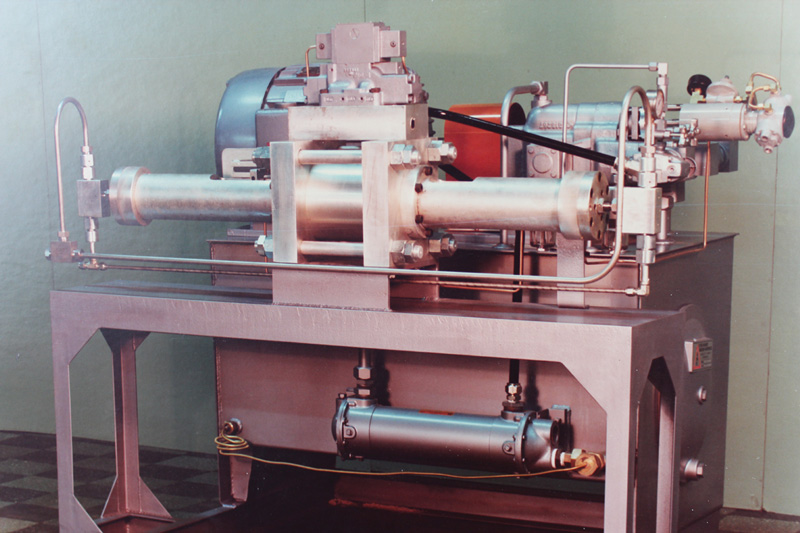

Due to poor health, Joe sold his company in 1963 to Ingersoll Rand, where they began experimenting with high pressure intensifiers, and discovered that “water under pressure” could cut most anything! In 1971, history was made when the very first waterjet cutting system was installed in Illinois at a cardboard box manufacturing facility.

In 2003, Sweden based Karolin Machine Tool (KMT) Co. expanded their tooling business by purchasing the poly and waterjet division from Ingersoll Rand. The Baxter Springs location currently employs 180+ people, is the corporate office of KMT Waterjet Systems, and is globally recognized as a leading manufacturer of waterjet systems. KMT waterjets are sold worldwide with offices in Brazil, Canada, China, France, Germany, India, Italy, Korea, Mexico, Poland, Spain, United Arab Emirates and the UK. Additionally, the polyethylene division continues to thrive and grow, and carries on the legacy of the McCartney name, where it is known worldwide as McCartney Engineering LDPE Products.

1947: McCartney Manufacturing Co. is founded by Joe McCartney in Baxter Springs, Kansas

1951: Began manufacturing High Pressure valves & fittings for the LDPE industry

1959: Designed and built first HP catalyst injection pump

1963: Ingersoll-Rand acquires McCartney

1964: Design and built first Tubular reactor & Intercoolers

1965: Built first phased intensifier HP-1

1971: Built first 4000 bar Waterjet intensifier

1986: Opened European sales & service office

1997: Installed new PF-1 phased catalyst injection pump

1999: Achieves ISO 9001 compliance

2001: Certified ISO 9001-2000 compliant

2003: KMT acquires IR Waterjet & IR McCartney

2012: KMT re-brands LDPE products as “McCartney LDPE”, under KMT Waterjet

2012: KMT re-brands LDPE products as “McCartney LDPE”, under KMT Waterjet

2012: Launch of the PF-3 Redundant Phase Flow Pump

2013: KMT & McCartney join SHAPE Technology Group

2022: McCartney celebrates their 75th anniversary

2024:  McCartney embraces its engineering heritage by reviving the original McCartney Manufacturing name, featuring a refreshed logo and a new website: www.mccartneymfg.com

McCartney embraces its engineering heritage by reviving the original McCartney Manufacturing name, featuring a refreshed logo and a new website: www.mccartneymfg.com